Load cells

Load cells: fields and areas of application

What they are, how they work: everything you need to know about load cells

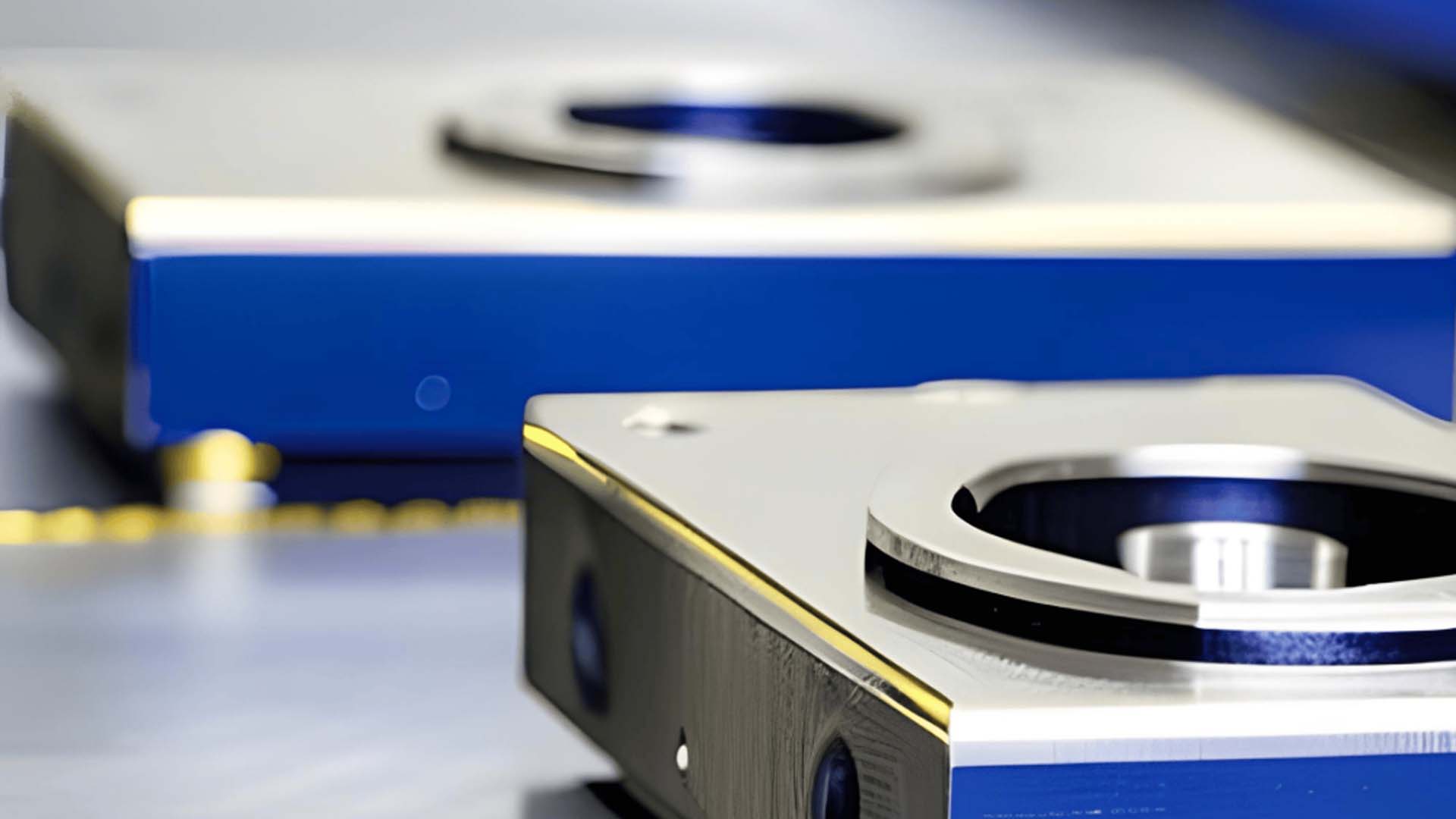

The load cells used today in industrial weighing systems are transducers, i.e. electronic components that can detect the force exerted on an object thanks to an electrical signal that varies according to the deformation caused by the force on the cell itself.

Generally, they consist of a flexible metallic body made of steel or aluminum onto which strain gauges are applied, i.e. instruments capable of reading the mechanical deformation experienced by the material, whether it is compression or tension. The shape change thus translates into a variation in the electrical signal of the strain gauge circuit based on Wheatstone.

Their history is interesting and dates back to the first spring devices for measuring weight invented in the 18th century, by scientists including Richard Salter. New paths opened up with the formulation of the Ohm’s law, which still bears the name of the German scientist today.

In 1938, the American Edward Simmons finally patented a resistive sensor used to measure the deformation of an object: this was the real turning point for weighing systems.

Load cells based on needs: our products

There are different types of load cells, with a wide temperature range that goes from grams to tonnes. Depending on the field of use, they are distinguished into:

- central cells

- compression cells

- shear cells

- tension cells

- bending cells

- flange cells

- pin cells

- Static torsiometers

Different interested sectors

But what are the sectors in which load cells prove essential? Among the main ones, we can certainly mention the following:

- Zootechnical field where they are used to automate certain processes such as the dosing and storage of feed;

- Dosing and sorting of food products;

- Gravimetric filling systems for bottles and cans;

- Weighing of transport and storage means (trucks, train wagons, ships, tanks, etc.);

- To avoid overloading in overhead cranes during the lifting phase and to comply with SIL regulations;

- Geotechnical field where they are used to determine the forces applied by tendons or the forces of nails or bolts in tunnels, diaphragms, and retaining walls;

- Safety scope on aerial platforms and cranes;

- Test benches in the field of car, motorcycle, and truck inspections;

- In the oil & gas sector during the laying of pipelines;

Furthermore, since the load cells must be able to withstand environmental effects, a specific temperature compensation mechanism is installed inside them to avoid alterations to the electrical resistance of the conductor.

Additionally available, depending on customer needs, are models with analog interfaces (0-10V or 4-20mA) and digital (CanOpen) integrated, ATEX or IECEx certified and used in areas where there is an explosion risk. Additionally, load cells that follow the OIML R60 accuracy classes used in the field of legal metrology and finally redundant (i.e., with dual channel) used in SIL systems (Safety Integrity Level).

The performance of a cell depends on many factors, among which the correct installation plays a crucial role. This is why NBC Elettronica Group supports and assists its customers from design to product implementation, with a post-sale assistance and repair service.

Recent articles